History

KRÖNER-STÄRKE: Tradition, progress and innovation

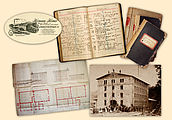

1900 Establishment of the business

At the age of 37, Hermann Kröner, a businessman and trained millwright, founds a wheat starch enterprise in the Bocketal in Ibbenbüren on 26 October 1900. The company bears his name. Soft, iron-free spring water, good railroad connections and reliable, down-to-earth employees are the main reasons for choosing this particular location.

1930 Generational renewal

In 1935, the legal practitioner Friedrich-Carl Kröner enters his parent's company at the age of 25. At that time the company was solely managed by his brother, Wilhelm Kröner, following the sudden death of his brother, Hermann Kröner in 1934. A year later, the company's founder Hermann Kröner dies. Despite two large fires and one interruption forced by World War II, production is continually modernized and expanded.

1950 Time of rebuilding

In the early 1950s, Friedrich-Carl Kröner becomes the sole owner of the firm. The production, office and laboratory facilities are expanded, storage capacities increased, silo shipment premises set up and the energy supply converted from coal to oil.

A sewage sprinkling facility is installed which, at that time, was unique in the wheat starch industry.

1970 Expansion of the corporate management team

At age 42, Hermann Kröner, grandson of the founder Hermann Kröner and nephew of Friedrich-Carl Kröner joins the company. In the following years, some parts of the plant are converted to more advanced technical processes. The introduction of a new hot air convection drier drastically reduces the time needed for drying the starch from originally taking a few days (drying in the sun) to a few seconds.

1980 KRÖNER-STÄRKE sets benchmarks

A computer-aided process control is integrated into the production process. The first outdoor silos are erected.

A slurry process developed in-house is now used for dough preparation. This reduces the fresh water consumption to one fifth of the former amount used. This process is later also applied by many other wheat starch producers.

The waste water treatment plant (biogas plant) is put into operation. It allows pre-cleaning of the waste water from the production with an efficiency of 96%. At the time of its commissioning, this plant is unique within the wheat starch industry; it is a groundbreaking pilot installation for the treatment of waste water.

In 1986, Friedrich-Carl Kröner dies and Hermann Kröner takes over the management of the company.

KRÖNER-STÄRKE implements extrusion production technology as a new pillar of the company.

1990 The third generation sets on expansion and organic issues

After the completion of his food technology studies, Dr Götz Kröner, son of the late Friedrich-Carl Kröner, joins the company at the age of 27. Together with Hermann Kröner, he heads the company.

The machinery is upgraded to meet the most advanced standards worldwide. The capacity of the company is tripled.

The energy supply is converted to gas. In 1995, the company is certified according to DIN ISO 9001.

One integral element of the corporate policy is to process exclusively untreated raw materials without the use of chemical aids. This approach is consequently intensified in 1997 with the processing of raw materials from controlled organic production sourced from BIOLAND contract partners. KRÖNER-STÄRKE becomes the largest producer of organic wheat starch in Europe.

Expansion and automation of the logistics department and strengthening of the extrusion production technology are the next steps. With the integration of a multi-component mixing plant and more roller driers, KRÖNER-STÄRKE specializes in the production of specialty products for the food industry.

2000 100 years of KRÖNER-STÄRKE: Safety and quality for our customers

The high commitment of KRÖNER-STÄRKE to quality is mirrored in the successful BCR, IFS, and QS certifications.

KRÖNER-STÄRKE increases its research and development staff and develops a range of new products for different fields of application.

A new production building is erected; it houses the latest roller technology and meets the highest food hygiene and product safety requirements. It provides ideal conditions for the production of specialty dietary products (e.g. baby food, geriatric food, gluten-free products) and functional Clean Label starches for different food applications.

The energy supply is converted from natural gas to brown coal dust as a crisis-proof solid fuel including power-heat cogeneration and an energy efficiency of 90 per cent.

The capacity of the biogas plant is doubled and expanded by an own power generation plant.

At the same time, a new and long overdue administration building is erected.

2010 Milestones

Following many years of continuous process optimization efforts, our gluten-free wheat starch SANOSTAR now complies with the strict limiting value of 1 mg gliadin in 100 g starch - achieved in a natural way and without the use of additives.

In 2012, a new logistics center with integrated mixing plant is inaugurated. Here different, highly susceptible products, including custom-made blends and premixes, can be filled on different filling plants safely and without the risk of carry-overs.